Introduction

Installation of advanced technologies such as Artificial Intelligence along with Internet of Things and robotics systems, under Smart industries drives manufacturing revolutions across all traditional production sectors. The system evolution uses machine-to-machine data exchange capabilities to drive data-based choices that boost operational output and productivity metrics. Smart solutions adopted by industries enable multiple benefits, such as enhanced resource management together with lower cost, and better flexibility of manufacturing systems.

Smart industries operate through their capacity to handle large amounts of data from interconnected sensors, which process information efficiently. An organization’s ability to collect data in real-time allows operational problem identification for forecasting maintenance needs and maximizing supply chain operations to decrease operational disturbances and product waste.

Through AI system integration, companies gain the ability to automate monotonous operations, which enables human staff to dedicate their efforts toward more challenging strategic endeavors. Such a change enhances both job satisfaction and enables organizations to develop new innovative strategies.

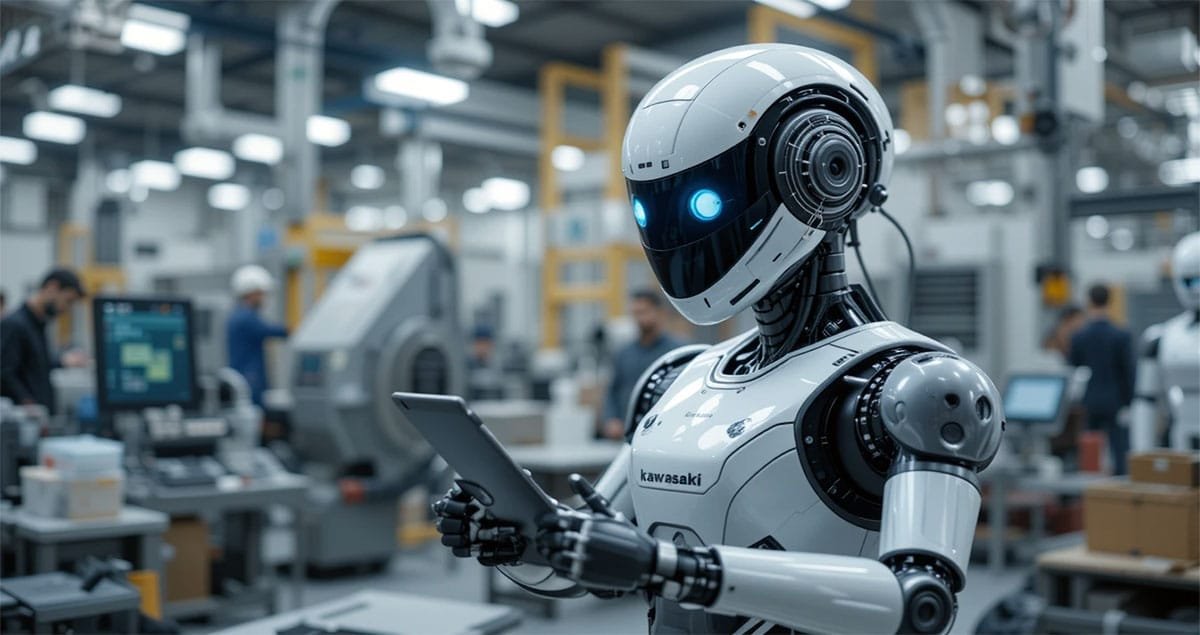

The nature of industrial facilities reveals their advancement through increased adoption of collaborative robots or cobots, which help human workers achieve better production efficiency. Human operators benefit from Kawasaki’s Corleo robots, which deal with repetitive, dangerous, and precise task execution to take on more demanding intellectual work. Organizations achieve marketplace dominance through the perfect coordination of automated systems with human operational skills in our evolving business environment. Smart industries enhance human operations instead of eliminating jobs.

Organizations can reach better market agility by adopting advanced automation which delivers the needed speed and flexibility in modern competitive environments. Progressive manufacturing development in the future will require permanent system integration to generate technological evolution with sustainable approaches.

Kawasaki’s Corleo Robot: An Overview

The Kawasaki Corleo robot brings next-level robotic technology to fulfill industry requirements of modern production. This robotic solution fully integrates into manufacturing operations because it enhances efficiency while improving productivity. Design features of this device combine a compact construction with an easy-to-use interface, which makes it appropriate for many applications across factory and assembly line operations.

The flexible nature stands out among the distinguishing traits of the Corleo robot system. The robotic system demonstrates the ability to conduct various tasks thanks to its design framework, which requires minimal manufacturing adjustments during application changes. Manufacturing industries benefit enormously from equipment that can quickly change its operational tasks when industries adapt processes toward dynamic production methods. The versatile nature of the Corleo robot proves that Kawasaki leads the way in maintaining innovation within robotic design.

Precision functions as a fundamental aspect of the Corleo robot system. This robot utilizes cutting-edge technological features to achieve its precise motor movements, which remain essential for delivering quality control in production. Manufacturing experiences major financial impacts because of minor production flaws, so robotic systems similar to Corleo must provide unflawed reliability. Sensors of advanced make ensure the robot operates precisely around predetermined margins thus driving better output standards.

The Kawasaki Corleo robot stands out because it demonstrates excellent adaptability features. The system provides solutions for complex industrial work demands which include both robot-human team functions along with self-operated safety tasks in dangerous areas. The adaptability competencies of this system both create safer operations and generate higher operational efficiency. Companies that implement Corleo robot features will develop better strategies to handle the rapid changes in technology.

Technological Advancements of the Corleo Robot

Industrial automation now has its most advanced representation found in the Kawasaki Corleo robot. Advanced artificial intelligence (AI) and machine learning functionality in the Corleo robot creates a substantial advancement in operational efficiency of smart industries. This robot system holds the capacity to process extensive data quantities through its AI framework and support improved decision processes, which enhance productivity levels and efficiency rates.

The Corleo robot stands out for its environmental learning capacity through applications of machine learning. The system adjusts operations through interaction with different systems and processes to optimize performance on an ongoing basis. Permanent self-improving capabilities of Corleo robots decrease operational downtime and reduce errors to maintain high precision in performed tasks. The ability to adapt functions efficiently serves workers in operations where production requirements alter frequently.

The AI analytics system deployed by Corleo makes it possible for organizations to easily implement predictive maintenance throughout operations. The robot system analyzes operational data to predict equipment failures, thus it helps identify maintenance requirements before breakdowns happen and reduces unexpected production disruptions while improving system reliability. The preventive maintenance strategy employed by this technology saves operational time and lowers unexpected maintenance expenses that lead to discontinued production.

Smart industries depend on Kawasaki Corleo robot technology because its superior capability helps maintain top operational performance in these applications. The robot demonstrates how automation technology transforms industrial operations because of its machine learning innovations, which trigger industrial process enhancements.

The Role of Corleo in Improving Efficiency

Modern manufacturing industries have increased their adoption of robotic systems, as demonstrated by Kawasaki’s Corleo robot, although this innovation remains among the peak examples of technological advancement for production efficiency. The Corleo robot serves production facilities through automation that conducts repetitive sequences of work to decrease manual work times substantially. The employment of Corleo robots with human operators enables industries to shift their skilled employees into strategic positions because the robot system performs assembly and inspection alongside packaging, resulting in accelerated production times.

Multiple research examples indicate the essential role Corleo plays in boosting industrial operational efficiency. The automotive manufacturer enabled improved assembly line management by using the Corleo robot in its manufacturing operations. After installing the robot system the business achieved two major outcomes that included halving the manufacturing time and minimizing human errors during tasks. The Corleo robot demonstrates its industrial significance by simultaneously boosting output quality as well as speeding up operations in modern manufacturing environments.

The electronics sector demonstrates a relevant adoption of Corleo robots for testing and quality assurance process optimization by an important firm. The testing phase created bottlenecks due to product launch schedules becoming longer before implementation. The Corleo robot automated testing operations efficiently for the company, so the assessment period became substantially shorter, resulting in a 40% reduction in duration. This led the company to shorten its time to market and simultaneously boost product reliability while obtaining improved customer satisfaction.

The Kawasaki-produced Corleo robot operates as a key element that boosts production efficiency in multiple industrial settings. Robotics enables the successful automation of processes and downtime reduction, which leads to operation streamlining that matches growing production needs.

Adaptability Across Various Sectors

The Kawasaki Corleo robot serves as a revolutionary agent that transforms several business sectors because of its flexible operating features. The versatile robotic system operates effectively between the production of automobiles and pharmaceutical operations and logistics facilities. The Corleo robot demonstrates high efficiency for automotive production work because it performs assembly, welding, and painting functions while ensuring precision during rapid operations. The Corleo robot demonstrates exceptional usefulness in automotive production because it executes complex procedures properly through strict security protocols.

The pharmaceutical industry benefits strongly from the adaptable characteristics of the Corleo robot. The robot performs essential functions, which include packaging pharmaceuticals and performing quality tests, and maintaining laboratory instruments. The robot operates with great dexterity to improve efficiency while minimizing contaminant risks, which are critical for protecting product quality in critical environments. Kawasaki provides customizable features that enable users to add unique attachments and programming capabilities that adapt the Corleo robot for specific pharmaceutical process requirements.

The Corleo robot succeeds in delivering powerful results within the logistics sector. The rising need for automated warehousing solutions has made this robot perform exceptionally well during inventory control tasks and product sorting operations, and order packaging processes. The robot adapts well to existing systems because it creates seamless connections between real-time data transmission and communication protocols. Improved time efficiency and lowered operational expenses become possible benefits for companies that use the Corleo robot. The Kawasaki Corleo robot stands out as an important technological asset that aids all industrial development while sustaining its core status in contemporary manufacturing processes.

Investment in Automation and ROI

Kawasaki’s Corleo robot automation technology stands as a necessary business strategy that businesses use to seek efficiency and cost-effectiveness. Organizations actively see a clear financial gain from machine system implementation in their operations. The implementation of Corleo technology delivers instant operational efficiency and economic gain to organizations through multiple operational benefits.

Organizations need to examine the financial effects of adopting the Corleo robot from Kawasaki because they will face reduced expenses for labor. The deployment of automated systems creates a focused workforce because companies can direct their employees toward valuable work tasks, which consequently drives productivity growth. The precise performance of Corleo reduces workplace errors and shortens operational interruptions, which leads to decreased maintenance expenses for machines.

The positive ROI benefits from better output quality standards. Robotics technology maintains repetitive duties with perfect precision to produce exceptional products that deliver superior satisfaction for customers. The development of a higher market share and enhanced sales generates increased overall revenue as a direct result. A wide-ranging research confirmed that companies implementing automated technologies boost their productivity by approximately 30 percent since they implemented robot systems such as Corleo.

Most businesses now experience fast returns on their primary funding. The Kawasaki Corleo robot benefits early adopters through fast cost recoupment, which occurs within a few years because of decreased expenses and heightened production output. Companies that adopt automated solutions today enjoy better competitive prospects for future growth as the smart industry environment develops. Robotics funding enables immediate monetary returns and simultaneously establishes long-term, sustainable business operations.

The implementation of Kawasaki’s Corleo robot serves as a financially effective approach that corresponds with the industry-wide automation evolution. The technology provides businesses with significant return on investment opportunities that lead to both reduced costs and increased productivity, thus enabling successful market competition.

Challenges and Considerations in Implementation

The implementation of Kawasaki Corleo robots brings various complications that businesses need to approach with great caution. Businesses face the biggest challenge in their effort to buy robotic solutions due to their high initial investment requirements. Businesses primarily affected by the costs of purchasing and implementing the Corleo robot will be small and medium-sized enterprises. Budgets restrict organizations, so they should look into financing options alongside phased implementation plans to better handle this issue.

Businesses need to execute detailed planning because integrating the Corleo robot within their current operations proves challenging. Management teams must review their active operational systems to discover ways for the natural integration of new technologies. OCURF inspections should trigger process revisions with possible system technological upgrades to guarantee operational compatibility. Systematic audits should be performed on the company infrastructure before implementation to address integration challenges because operational disruptions and inefficiencies follow when these issues remain unresolved.

An organization must not dismiss the importance of training its employees among critical considerations. The labor force needs thorough training to develop proper skills when using and interacting with the Corleo robot. Organizations need to develop extensive training solutions that combine practical workshops and test environments, and training service collaborations to achieve full operational readiness. Airlines must dedicate fiscal support for these projects and invest in staff preparation programs so their team members become proficient with new operating systems. Companies that start mentorship programs will enable experienced personnel to assist new staff members during their transition to new systems.

Enterprises that choose Kawasaki’s Corleo robot for operational enhancement will encounter expenses along with implementation difficulties and training challenges for their staff. Organizations that implement strategic planning and resource allocation will successfully tackle these challenges and achieve technical transformation success.

Future Trends in Robotics and Industry 4.0

Technological advancements under Industry 4.0 lead to the complete digitization of industrial operations through manufacturing processes. Robotics systems drive fundamental operational changes for businesses throughout this ongoing industrial development period. Modern smart factories demand the increasing adoption of autonomous robots which Kawasaki introduces through its Corleo model. Manufactured to operate concurrently with human professionals, these robots boost manufacturing success rates while protecting both people and assets. Industrial machines communicate effortlessly with each other so they demonstrate the linked nature which marks Industry 4.0 operations.

The evolution of robotics technology is divided between artificial intelligence development and machine learning system advancement, which enhances robotic functions through self-operational capabilities. Enhancements of these technological advancements will enable robots to perform both continuous operations along autonomous adjustments for making instant decisions in real-time. Industrial transformation is essential for businesses to handle variable market requirements and boost operational performance. The Kawasaki Corleo robot operates with capabilities that fulfill smart industrial specifications through its adaptable performance features and precise functions.

Industry 4.0 robots will gain new capabilities through the upcoming developments of the Internet of Things (IoT). Real-time operational performance data that robots obtain through internet connections enables them to perform predictive maintenance along with reducing operational downtime. The growing adoption of connected operations by industries indicates there will be increased possibilities for utilizing robotics in workflow procedures. The transformation achieves two objectives by maximizing operational performance along with sustainable practices that lower waste quantities and energy consumption.

The future direction of robotic technology in industry keeps advancing in the context of human-robot combined work processes. Workers benefit from more efficient operations together with better ergonomics, since collaborative robots support them in various tasks. The Kawasaki Corleo stands as the standard feature for this concept, which exhibits robotic support systems that boost human capabilities instead of replacing them to promote workplace productivity through innovation.

Conclusion: Embracing the Future with Kawasaki Corleo

Smart industry evolution depends on merging advanced technologies while the Kawasaki Corleo robot sets an example of this development trend. This post explores the major operational changes that robotics provides for accuracy and efficiency alongside industrial flexibility. The Kawasaki Corleo robot exists as a key technological opening that industries must acknowledge when they need to maintain speed with modern technological developments.

The Corleo robot enhances operations through its automated systems that provide instant data analytics for making better decisions. Organizations need adaptability in today’s competitive marketplace since market trends and customer needs directly impact their competitive performance. By adopting new technology, businesses achieve better resource management, together with reduced operational costs, along increased profitability.

FAQs

The Kawasaki Corleo Robot perfectly fits smart industrial applications for what reasons?

- The Kawasaki Corleo Robot with its automated system provides precision control and flexible operation which aligns perfectly with smart industry needs to enhance productivity and operational uptime while stimulating technology-based advancements.

What role does the Corleo Robot play in boosting technological development in manufacturing operations?

- The Corleo Robot system improves manufacturing production lines through robots with artificial intelligence, along with real-time analysis software that enables technological advancement in manufacturing.

The Kawasaki Corleo Robot serves to improve factory automation through what features?

- The integration of Corleo Robot into existing systems enables factory operators to benefit from smart automation and reduced labor strain while ensuring consistent performance which leads to intelligent factory automation.

9. Does the Kawasaki Corleo Robot hold enough features to be considered a future solution under Industry 4.0 guidelines?

- Definitely. Future industries will benefit from the Corleo Robot through its built-in features of IoT connectivity and data intelligence, which adapt to the changing requirements of modern industries.

10. Does Kawasaki Corleo Robot offer capabilities for customization, in particular industrial usages?

- Yes, it’s highly customizable. Businesses can modify the robot according to welding operations and material handling, as well as for inspection work and packaging, and assembly procedures based on their individual operational requirements.

Ls168game? Hmmm, never heard of them before but always up to find interesting stuff. Checking it out now! ls168game

Thinking about trying out MM99slot. I’m really hoping there are some progressive games. Learn more here: mm99slot

88iat.net… Hmm, I don’t immediately recognize that one. Looks like a pretty standard interface. Might be a diamond in the rough. If you are keen to find a place to play, give it a try: 88iat